Introduction:

Water, heating, and gas are the “lifeblood” of buildings, and their smooth flow depends on precise and reliable piping systems. Whether it’s home renovation or large-scale projects, the choice of piping installation methods directly determines the system’s lifespan and safety. Faced with various materials such as copper pipes, PEX pipes, and PVC pipes, mastering mainstream installation techniques and their core tools is an essential skill for every professional. This article will take you through the fundamentals of pipe installation and reveal why crimping technology is rapidly becoming the preferred choice in modern pipe engineering.

1. Pipe Systems: The “Lifeline” of Buildings

Modern buildings rely on three major pipe systems:

Water Supply System: Delivers clean domestic water (cold/hot water).

Drainage System: Collects and discharges wastewater and sewage.

Specialized Systems: Heating (radiator pipes), gas supply, fire sprinklers, etc.

Common Pipe Materials:

Copper Pipes (Copper): The traditional choice, known for high-temperature and high-pressure resistance, antibacterial properties, and long lifespan, widely used in high-quality hot and cold water pipes and heating systems.

PEX Pipe (Cross-linked Polyethylene): The modern newcomer, offering excellent flexibility, freeze resistance, quick installation, and high cost-effectiveness, it has become the mainstream choice for residential hot and cold water pipes.

PVC/CPVC Pipe: The economical option, resistant to corrosion, primarily used for drainage, cold water, and certain chemical medium transportation (CPVC can withstand hot water).

Galvanized steel pipes: Durable and robust, they were once widely used for water supply but are gradually being replaced due to their tendency to rust and scale.

Cast iron pipes: Heavy and soundproof, they are primarily used for main drainage risers in buildings.

Key tip: Material properties (rigidity/flexibility, temperature resistance, cost) are the primary considerations when selecting installation methods!

2. Overview of the Five Major Pipe Installation Methods

Connecting pipes is like “building with blocks,” with different techniques each having their own advantages:

Threaded connection (screw connection) – a rigid “mechanical lock”

Principle: External threads are machined at the pipe ends, which are then tightly screwed into fittings with internal threads (elbows, tees, etc.), with sealing achieved using PTFE tape or hemp fiber packing.

Applications: Galvanized steel pipes, certain thick-walled copper pipes, and malleable cast iron fittings.

Advantages: Removable, no special equipment required (a die stock is needed).

Disadvantages: Complex process, sealing relies on skill, threaded areas are prone to becoming weak points leading to leaks, and the water flow cross-section is reduced.

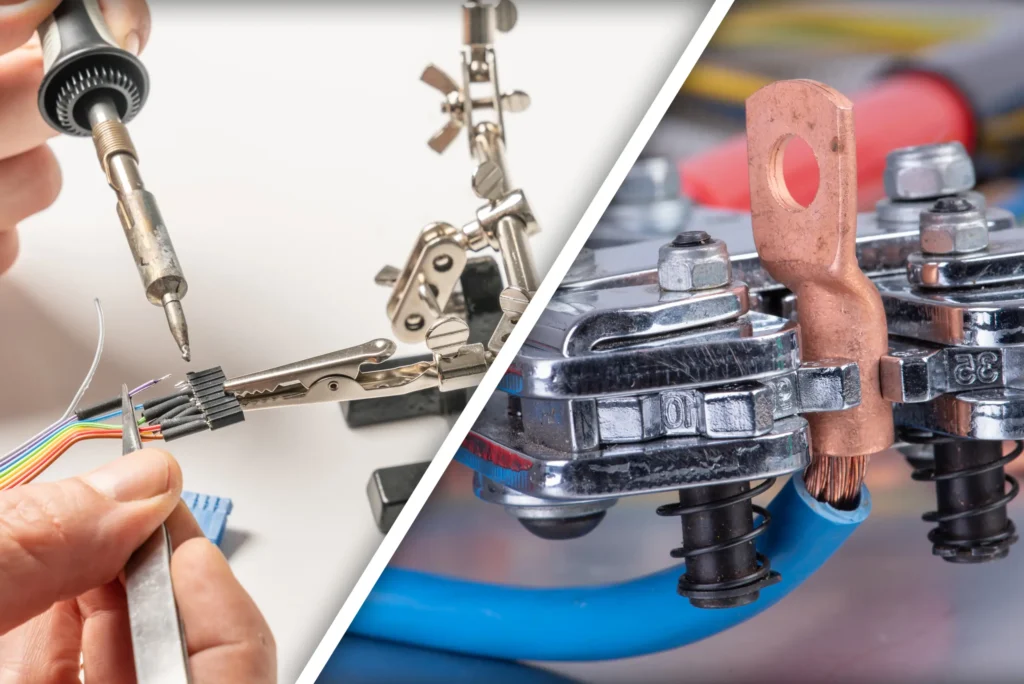

Welding (Brazing/Fusion Welding) – The “thermal fusion” of metals

Principle (common in brazing): Clean the pipe and fitting interfaces, apply flux, heat with a flame, melt the solder (tin solder/silver solder) with a melting point lower than the pipe material, and capillary-fill the gaps. After cooling, a strong connection is formed.

Applications: Copper pipes, steel pipes.

Advantages: High connection strength, excellent sealing, smooth joints without reduced diameter.

Disadvantages: Requires open flame operation, posing significant safety risks; high technical requirements; generates fumes requiring ventilation; non-removable; heat-affected zone may impair material properties.

Solvent Adhesion (Glue Bonding) – “Chemical Fusion” of Plastics

Principle: Apply specialized solvent adhesive to the joints of PVC/CPVC pipes and fittings, dissolve the surface materials, then press together to allow molecular chains to intertwine and cure, forming a monolithic structure.

Application: PVC pipes, CPVC pipes.

Advantages: Relatively simple operation, low cost, reliable connection (when properly executed).

Disadvantages: Only applicable to specific plastics; dependent on adhesive quality and uniform application; curing requires time; non-disassemblable; emits a pungent odor.

Flange Connection – The “Strong Bolt Lock” for Large Diameters

Principle: Weld or thread flanges onto the pipe ends, insert a gasket between the two flanges, and secure with bolts and nuts to achieve sealing.

Applications: Large-diameter pipelines (main water supply lines, industrial pipelines), valves, pumps, and other equipment interfaces.

Advantages: Removable, high pressure rating, reliable sealing, and easy maintenance.

Disadvantages: Bulky, space-consuming, high cost, and slower installation.

Push-in/Quick-connect – Ultimate “Convenience”

Principle: Utilizes precision O-rings and tooth structures inside the fitting. After cutting and preparing the pipe, simply force it into the fitting until it reaches the end, and the internal mechanism automatically locks and forms a seal.

Applications: PEX pipes, copper pipes (specific fittings), PE-RT pipes.

Advantages: Extremely fast installation (no tools required), removable (requires a special removal ring), suitable for confined spaces.

Disadvantages: Highest fitting cost; extremely high requirements for pipe end cutting and processing; some users question its long-term reliability (especially in high-temperature water systems).

3. The King Arrives: Crimp/Press Connection – Revolutionary “Mechanical Cold Connection”

Crimp technology is emerging as the mainstream choice for modern pipe installation, especially for copper and PEX pipes, thanks to its outstanding comprehensive performance!

Core Principle: No heating or chemical reactions required! Using the powerful mechanical force of specialized crimping tools, specially designed metal sleeves (copper rings, stainless steel sleeves) or the fitting body are uniformly compressed and deformed at the joint containing an O-ring rubber seal.

The deformation of the sleeve/fitting creates a permanent clamping force.

The compressed O-ring forms a dual sealing barrier between the outer wall of the pipe and the inner wall of the fitting.

Achieves a secure and reliable sealed connection between the pipe and fitting.

Core Advantages (Why Does It Stand Out?):

Safe and Reliable: No open flame required (eliminates fire hazards), no chemicals required (non-toxic and environmentally friendly), mature O-ring sealing technology proven over the long term.

Efficient and Quick: Single-point connections typically take only a few seconds (after cutting and preparation), with construction speeds far exceeding welding and threading, significantly reducing labor and time costs.

Easy to Master: Operations are relatively simple, requiring only basic training to master, with lower reliance on worker skills compared to welding.

Quality Control: Crimp marks are visible to the naked eye, and specialized gauges (Go/No-Go) can be used for quick non-destructive testing, providing intuitive and reliable quality assessment.

System advantages: Reduces thermal stress (compared to welding), does not cause diameter reduction (compared to threaded connections), and is suitable for both exposed and concealed installations.

Wide application: Perfectly compatible with the two main types of modern pipes—copper pipes and PEX pipes (note that tools and rings are not interchangeable!), and also used in stainless steel pipe connections.

Applicable pipe materials:

Copper Tube Crimp: Use copper crimp fittings with built-in O-rings and copper crimp rings (for some systems), paired with manual/electric crimping pliers.

PEX Tube Crimp (Crimp): Use copper or stainless steel open-ended sleeves + matching fittings, paired with PEX-specific manual/electric crimping pliers. (PEX also has Cinch and Expansion methods.)

Key operational points (foundation for success):

Perfect cutting: Use a pipe cutter to make a vertical cut, ensuring the end is flat.

Thorough deburring: All internal and external burrs must be completely removed to prevent damage to the seal or obstruction during insertion.

Depth marking: Precisely mark the insertion depth line required by the fitting at the pipe end.

Full insertion: Forcefully push the pipe into the bottom of the fitting (often accompanied by a “click” sound) .

Proper Positioning (PEX-Specific): For PEX crimping, first place the sleeve over the pipe, insert the fitting, then pull the sleeve back to the fitting shoulder.

Precise Crimp: Use a crimping die matching the pipe diameter, position the crimping tool perpendicular to the joint, and apply full pressure until the tool releases/closes.

Mandatory inspection: Each crimping point must be inspected using a dedicated gauge!

Crimping warning: Copper pipe tools ≠ PEX pipe tools! Mixing the two will inevitably lead to connection failure and leakage!

4. How to choose the installation method?

Decision-making requires comprehensive consideration:

Pipe material: The decisive factor (copper brazing/PEX crimping/PVC adhesive bonding).

Application scenario: Cold water/hot water/heating/gas/drainage? Exposed installation/concealed installation? Space constraints?

Budget cost: Consider material costs (pipes + fittings), tool investment, and labor costs.

Technical requirements and standards: Worker skill level? Are local regulations mandatory for specific connection methods (especially for gas pipes)?

Efficiency requirements: Are there tight deadlines?

Conclusion: Crimp technology has established an unquestionable leading position in copper and PEX pipe installation due to its safety, reliability, efficiency, and ease of inspection. Understanding the principles and applicability of various installation methods, particularly mastering the core principles of crimping, is the fundamental guarantee for ensuring a leak-free and long-lasting pipeline system.